lycoming o 320 compression test|How to Check Compression : discount store At least in the US, you can't legally release a Lycoming if it's 60 or under. Continentals are another matter. I think 47 was the lowest we had on the 520s before turning . 9 de jun. de 2023 · Related: 12 Tough Interview Questions and Answers 8. Ask questions about the question Sometimes, a person asking a challenging question does so because of an underlying issue. It's helpful to understand this person's perspective and motives before engaging in a potentially combative exchange.

{plog:ftitle_list}

If you are looking for free Brazzers porn videos, you have come to the right place. xHamster offers you tons of Brazzers hardcore sex vids, featuring the hottest babes, the biggest tits, and the most intense orgasms. Whether you like blondes, brunettes, milfs, teens, lesbians, or anal, you will find something to satisfy your fantasies on xHamster Brazzers channel. .

As required to determine cylinder compression. The condition of the working parts in the combustion chamber of a cylinder can be determined by measuring the static leak rate of the cylinder as compared to the leak rate through an orifice of specified size. At least in the US, you can't legally release a Lycoming if it's 60 or under. Continentals are another matter. I think 47 was the lowest we had on the 520s before turning .

Technical Question

Its time for the Warrior to come into the shop for its 100hrs inspection. Part of that inspection is to check the compression of all of the cylinders.More information may be gained rather quickly by doing a compression check to locate any low compression cylinders. Do a boroscope inspection to determine the condition of the . A test to determine the internal condition of the com- bustion chamber cylinder assembly by ascer- taining if any appreciable internal leakage is occurring is compression .Manual leaning may be monitored by exhaust gas temperature indication, fuel flow indication, and by observation of engine speed and/or airspeed. However, whatever instruments are used in .

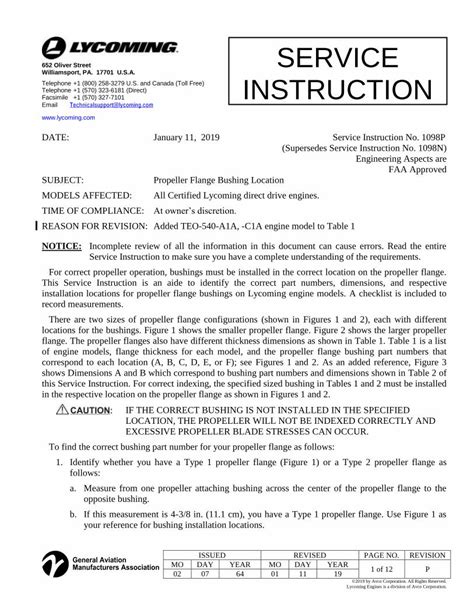

Test procedures can be found in AC 43.13-1B, Lycoming Flyer Key Reprints, Lycoming Service Instruction 1191A, and TCM Service Bulletin SB03-3.

Instructional video showing how to check compression using a differential compression tester on on Lycoming engine. Lycoming A&E series engines run 4 individual main bearing shells up front and the B&D series run 2 bearing shells rotated 90 Deg to the case halves. (A&E series engines are . A compression test could tell you that air was leaking past the exhaust valve, but with the borescope you could tell whether it was because of a benign glob of lead on the seat that would quickly resolve itself the next time .The Lycoming oil additive P/N LW-16702 must be added to the O-320-H and O/LO-360-E engines at airframe installation, and every 50 hours thereafter or at every oil change. An FAA-approved lubricating oil that contains, in the proper amount, an oil additive equivalent to LW-16702 will meet the requirements for the additive as stated in Lycoming .

The compression test is a very useful tool to help determine the internal condition of cylinders, but it has limitations and must be used in conjunction with other non-invasive tests. . Service Instruction No. 1191A .Lycoming’s four-cylinder 320 Series engines produce 150 or 160 hp at 2,700 RPM. These engines power numerous popular aircraft produced by companies like Cessna, Piper, and kit manufacturers such as Van’s and Glasair. The 320 .

Lycoming O-235 and O-290 Series Approved by FAA 5th Edition Part No. 60297-9 652 Oliver Street January 2007 Williamsport, PA. 17701 U.S.A. 570/323-6181. O-235 and O-290 Series Operator’s Manual . Two compression rings and an oil regulating ring are employed on all pistons. In addition, the O-235 series employs an oil scraper ring below the .Static test your Rotax 912 cylinder compression with 80 psi shop air. No cranking required. Just find TDC and pressurize cylinder to 80 psi. Left gauge allows you to regulate pressure with built-in regulator valve. . The 18MM unit is used on both Lycoming and Continental engines. View in Catalog View in Catalog Submit: Submit: Contact. Toll . Approved Fuel Injectors, Fuel Manifold Assemblies, and Fuel Nozzle Assemblies for Lycoming Engines. Service Instructions | 12.01.23. Service Instruction No. 1589. Exhaust Bypass Valve Assembly Replacement. Service Instructions | 12.01.23. Service .

Lycoming Part Number: MM-TEO-540-A1A Contact Us: Mailing Address: Lycoming Engines . S.I. 1191 10/18 Cylinder Compression S.I. 1204 10/18 Exhaust Flange Gaskets . S.I. 1462 10/18 Propeller Oil Control Leak Test ProcedureS.I. 1191 01/17 Cylinder Compression Check S.I. 1241 01/17 Pre-oil the Engine Prior to Initial Start S.I. 1267 01/17 Piston Pin Plug Usage S.I. 1285 01/17 Non-Destructive Testing of Lycoming Engine Parts S.I. 1290 01/17 Repair of Oil Leakage at Crankcase Thru-Stud Locations; Assembled and Unassembled Engines. Removed Table 1 – Alternate Piston Ring P/Ns. Changed all table references from Table 2 to Table 1. Updated listing for low compression O-235 series, including addition of notes on page 17. Add listing for O-360-J2A and O-540-F1B5 .October 5, 2015 MODELS AFFECTED IO-320, -360, -390, -540, -580; AEIO-320, -360, -390, -540; LIO-320-B1A; O-320-B2D, -D1D; (L)O-360-A1H6, -A1N6, -A1G6D; HIO-360; LIO-360; O-360-A1H, -A2G, -A4G, -A4J, -A4K, -A1G6, -C1F, -C4F; O-540-L3C5D; and TO-360-C1A6D TIME OF COMPLIANCE 50 hours from the issue date of this Service Bulletin or the next regularly .

Had s prebuy done in August 2018, all cylinders were mid 70s. Annual from 2018 and all cylinders were mid 70s. Today was IFR so couldn’t fly and warm it up properly just did a ground run up. Cylinder 4 tested in the 30s, cylinder 2 tested in the 50s and the other 2 were in the 70s. IA says.Service Bulletins Letters and Instructions INDEX SSP-112-13 February 2022 652 Oliver Street Williamsport, PA 17701 U.S.A. Phone: Main Office U.S. and Canada Toll Free +1 (800) 258-3279DATE RELEASED: December 2011 TITLE: O-320-E2B & -E2C Parts Catalo DOCUMENT PART NUMBER: PC-203-5 MODELS AFFECTED: O-320-E2B, O-320-E2C. Skip to main content. Utility. Gear Store; iE2 Portal; Find a Distributor . Lycoming has a worldwide product support network so you can access the technical, training, and service information you need at your . Remember, some of the smaller production engines have 5 inch or larger cylinder bores (e.g. Lycoming O-320-A1A has a cylinder bore of 5.125 inches). Therefore, an orifice of 0.060 diameter should be used to perform the compression test. See AC 43.13-1B, Chapter 8, paragraph 8-14 for more information.

LYCOMING ØŒ SERIES OPERATOR’S MANUAL SECTION 1 O-320 DESCRIPTION SECTION 1 DESCRIPTION General – The Lycoming O-320 aircraft engine is a four cylinder direct drive, horizontally opposed, wet sump, carbureted, air cooled engine. In referring to the location of the various engine components, the parts are described in their relationship

All fixed wing and rotary wing aircraft (horizontal installations only) with Lycoming reciprocating aircraft engines installed . TIME OF COMPLIANCE. After field overhaul. This Service Instruction identifies the necessary steps for engine breakin, including engine preparation for ground operational tests, flight tests, afterflight tests, and . A: Alan, if you do have, in fact, a Lycoming O-320-E2D, you don’t need to go any further as the answer is simple. To my knowledge, the O-320-E2D was never bumped up to 180 horsepower (legally that I am aware of) because of the front main bearing configuration, which is the same as the Lycoming O-235 series of engines.

O-320-D2J Illustrated Parts Catalog Lycoming Part Number: PC-O-320-D2J (Supersedes part of PC-203-9) For additional information: Mailing address: Lycoming Engines 652 Oliver Street Williamsport, PA 17701 U.S.A. Phone: Factory: U.S. and Canada toll free: +1(800) 258-3279 International Customers: +1(570) 323-6181 In fact I did one today on a Maule MX-7 /180..or should I say I coached the owner thru the evolution. The compression on the cylinder was 40/80 cold, after the compression was 76/80 cold. The owner called me because the A&P wanted to pull the cylinder, and send it out to be re-built. Fixing a cylinder in place is always better.

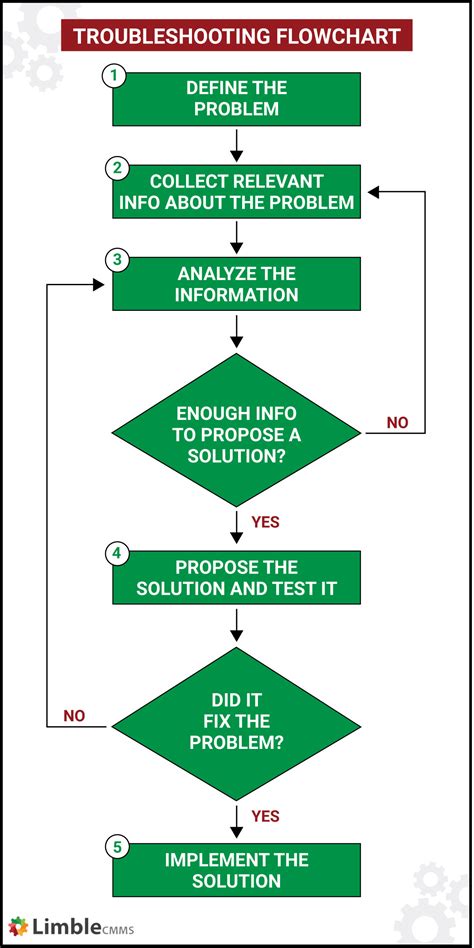

TROUBLE SHOOTING GUIDE

NOTE: The ATS 2EM Differential Pressure Tester has a .040” orifice as required by Teledyne Continental SB03-3 Service Bulletin, and is the proper type of instrument to test ALL Teledyne Continental engines in accordance with the aforementioned bulletin. The ATS 2EM also complies Textron Lycoming SI-1191A Service Instruction and is appropriate for ALL Textron Lycoming . Lycoming O-320 exhaust valve. Note the symmetrical “bullseye” appearance indicating a healthy valve. This is a very sick exhaust valve on the verge of failing catastrophically. Note the asymmetrical appearance: That’s bad! . A compression test could tell you that air was leaking past the exhaust valve, but with the borescope you could .Page 1 Operator’s Manual Lycoming O-320 Series Approved by FAA 3rd Edition Part No. 60297-30 October 2006 652 Oliver Street Williamsport, PA. 17701 U.S.A. 570/323-6181.; Page 2 652 Oliver Street Williamsport, PA 17701 U.S.A. Phone: Factory: 570-323-6181 Sales Department: 570-327-7268 Fax: 570-327-7101 Lycoming’s regular business hours are Monday through .

Instructional video showing how to check compression using a differential compression tester on on Lycoming engine.Specifications for the Lycoming O-320 and O-360 series of engines with data that includes compression, horsepower, RPM, TBO, dimensions, dry weight, and mount type. The Lycoming O-320 and O-360 series engines are four-cylinder, direct-drive, horizontally opposed, air-cooled models. The cylinders are of conventional air-cooled construction with .

During a compression test you are only putting in 80 psi on a relatively cold cylinder (despite having run it prior) Sometimes you can rock it back and forth and you will hear the ring snap into a good seat and the reading will jump 10 or 20 points. . because Continental doesn't make a 320 and he wasn't asking about a 320, he was asking about . The compression pressures are marginal - but they are not the best indicator of engine condition. I'd suggest a leakdown test is a better indicator of condition. The O-235-C1 only runs a 6.75:1 compression ratio, but 60psi is regarded as . ENGINE INSPECTION AFTER OVERSPEED DATE: April 9, 2020 SUBJECT: Engine Inspection after Overspeed MODELS AFFECTED: All Lycoming piston engines. TIME OF COMPLIANCE: As required by the subject bulletin. REASON FOR REVISION: Added new engine model IO-390-D to Table 1. Added new steps in Table 4 to include EIS Overspeed. .

compression tester car mechanic simulator 2018

Service Instruction No. 1191 A

1 de dez. de 2021 · The gaita de furro or gaita maracaibera is the most popular and standard form of this musical genre. If you’ve heard a gaita before, chances are it’s a gaita de furro. It always uses the five basic gaita instruments: furro, cuatro, tambora, charrasca and maracas.

lycoming o 320 compression test|How to Check Compression